Mashiinnada Shaambadaynta Xawaaraha Sare ee HC-25T

Qodobbada Farsamada ee ugu Muhiimsan:

| Moodel | HC-16T | HC-25T | HC-45T | |||||||

| Awoodda | KN | 160 | 250 | 450 | ||||||

| Dhererka istaroogga | MM | 20 | 25 | 30 | 20 | 30 | 40 | 30 | 40 | 50 |

| SPM-ka ugu badan | SPM | 800 | 700 | 600 | 700 | 600 | 500 | 700 | 600 | 500 |

| SPM ugu Yar | SPM | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Dhererka lafta | MM | 185-215 | 183-213 | 180-210 | 185-215 | 180-210 | 175-205 | 210-240 | 205-235 | 200-230 |

| Hagaajinta dhererka meydka | MM | 30 | 30 | 30 | ||||||

| Aagga sibidhka | MM | 300x185 | 320x220 | 420x320 | ||||||

| Aagga Bolster | MM | 430x280x70 | 600x330x80 | 680x455x90 | ||||||

| Furitaanka Bolster | MM | 90 x 330 | 100x400 | 100x500 | ||||||

| Matoorka ugu weyn | KW | 4.0kwx4P | 4.0kwx4P | 5.5kwx4P | ||||||

| Saxnaanta | Darajada Gaarka ah ee JIS/JIS | Darajada Gaarka ah ee JIS /JIS | Darajada Gaarka ah ee JIS/JIS | |||||||

| Wadarta Miisaanka | TON | 1.95 | 3.6 | 4.8 | ||||||

Astaamaha ugu Muhiimsan:

1. Waxaa laga sameeyay bir la shiiday oo aad u xoog badan, cadaadiskana waa la yareeyay si loo helo adkeysi ugu badan iyo saxnaan waqti dheer ah. Waa tan ugu fiican wax soo saarka joogtada ah.

2. Tiirar laba jibbaaran iyo hal qaab-dhismeed hagaha tuubada, oo laga sameeyay geed naxaas ah halkii loox dhaqameed si loo yareeyo is-qabsiga. Ku shaqee saliidayn qasab ah si loo yareeyo cimriga cadaadiska kulaylka ee qaab-dhismeedka, kor u qaad tayada shaambadda iyo kordhinta cimriga adeegga mashiinka.

3. Qalabka Balancer ee ikhtiyaari ah si loo yareeyo gariirka, loo sameeyo saxnaan sax ah oo deggan.

4. Way ku habboon tahay in la hagaajiyo laadhuuga iyadoo la adeegsanayo tilmaame dhererka laadhuuga iyo qalabka qufulka haydarooliga.

5.HMI waxaa maamula microcomputer. Qiimaha bandhigga iyo nidaamka la socodka cilladaha. Way fududahay in la shaqeeyo.

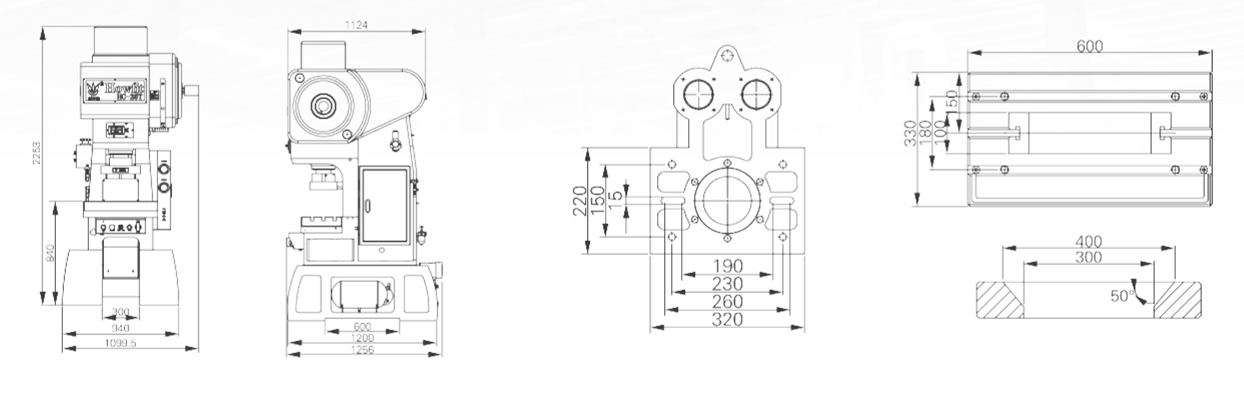

Cabbirka:

Alaabooyinka Saxaafadda:

Ka taxadaritaan:

✔ Haddii geeska feerka iyo qolofta qaloocan ay duugoobaan, waa in la joojiyaa isticmaalka oo la shiido waqti ka dib. Haddii kale, heerka xirashada geeska furka ayaa si degdeg ah loo ballaarin doonaa, xirashada qalabka furka ayaa la dedejin doonaa, tayada mashiinka shaambada xawaaraha sare leh iyo cimriga qalabka furka ayaa yaraan doona.

✔ Caaryada waa in dib loogu celiyaa meeshii loogu talagalay waqti ka dib marka la isticmaalo, isla markiibana lagu daaweeyaa saliid iyo miridhku u adkaysto.

✔ Si loo hubiyo cimriga adeegga ee qalabka, waa in si joogto ah loo beddelaa gu'ga qalabka, taasoo si weyn uga hortagi karta in waxyeellada daalka ee gu'gu ay saameyn ku yeelato isticmaalka qalabka.

✔ Ugu dambeyntii, haddii aad isticmaasho wax qalab ah ama haddii kaleba, fadlan si naxariis leh u hubi badbaadadaada.

Su'aalaha Badiya La Weydiiyo

- Su'aal: Ma ku habboon tahay soo saaraha mashiinka saxaafadda mise ganacsade mishiin?

Jawaab: Howfit Science and Technology CO., LTD. waa soo saaraha Mashiinka Saxaafadda oo ku takhasusay wax soo saarka iyo iibinta Xawaaraha Sare ee Saxaafadda iyadoo leh shaqo 15,000 m² ah muddo 15 sano ah. Waxaan sidoo kale bixinnaa adeeg habayn mashiinka saxaafadda xawaaraha sare leh si loo daboolo baahiyahaaga gaarka ah.

Su'aal: Ma ku habboon tahay inaad booqato shirkaddaada?

Jawaab: Haa, Howfit waxay ku taal magaalada Dongguan, Gobolka Guangdong, Koonfurta Shiinaha, halkaas oo ay ku taal meel u dhow wadada weyn ee weyn, khadadka tareenka dhulka hoostiisa mara, xarunta gaadiidka, isku xirka bartamaha magaalada iyo xaafadaha, garoonka diyaaradaha, saldhigga tareenka iyo ku habboon in la booqdo.

Su'aal: Imisa Dal Ayaa Ku Guuleystay Heshiiskii Aad La Gashay?

Jawaab: Ilaa hadda si guul leh ayaa heshiis ula gashay Ruushka, Bangladesh, Jamhuuriyadda Hindiya, Jamhuuriyadda Hantiwadaagga ee Vietnam, Dowladaha Mexico ee Midaysan, Jamhuuriyadda Turkiga, Jamhuuriyadda Islaamiga ah ee Iiraan, Jamhuuriyadda Islaamiga ah ee Bakistaan iyo iwm.

Falanqaynta Modal ee Mashiinka Korontada ee Xawaaraha Sare ee Lamination Press Crankshaft

- Crankshaft waa qayb muhiim ah oo ka mid ah cadaadiska loo isticmaalo wareejinta dhaqdhaqaaqa iyo awoodda. Inta lagu jiro shaqada, culaysku aad buu u adag yahay, wuxuuna sitaa culays saameyn weyn leh, marka lagu daro, sidoo kale waxaa saameeya doorka cadaadiska beddelka ah, wuxuu si dhab ah u saameeyaa xoogga daalka crankshaft, wuxuuna u nugul yahay daalka. Iyadoo la horumarinayo cadaadiska lamination-ka xawaaraha sare ee matoorka korontada, culayska iyo xaaladaha shaqada ee crankshaft ayaa aad u daran. Marka la eego ficilka culayska soo noqnoqda, daalka dhicis ah ayaa dhaca. Markaa waxaa lagama maarmaan ah in la falanqeeyo astaamaha firfircoon ee crankshaft.